How It Works: Fuel Cell Stack Cooling Package (FC-SCP)

As the push to zero-emission mobility continues, the integration of a fuel cell stack to extend the range of a Commercial Electric Vehicle is gaining traction. Simplistically, a fuel cell is an electrochemical cell that converts the chemical energy from a hydrogen fuel to electricity through an electrochemical reaction with oxygen or other oxidizing agent. The electricity is then used to charge the battery pack in the electric vehicle, allowing for extended range.

During the electrochemical process, waste heat will be generated that needs to be managed to keep the stack in a safe, optimal operating temperature range which will vary from stack to stack, depending on the fuel cell design. In commercial fuel cell vehicles, efficiencies of around 50-60% during the electrochemical reaction are not uncommon, meaning a significant amount of waste heat will be generated that needs to be removed. To do this, often, a coolant circuit will flow around the fuel cell stack, transferring heat from the stack to the coolant. The coolant then flows to a cooling package to reject heat to the ambient air before returning to the stack.

A key consideration for fuel cell vehicles is safety. Today’s fuel cell technology requires a low conductivity (high resistance) coolant to prevent leakage current from flowing between the stack and the rest of the system. If leakage current does flow through the coolant, it can cause short-circuiting, induce galvanic corrosion, and electrolyze the coolant, reducing engine efficiency. Generally, non-corrosive coolants are used; however, over time, the heat exchange interface in contact with the coolant will begin to wear, increasing the conductivity of the coolant and resulting in potentially excessive leakage current. Failure to manage this problem will lead to increased maintenance costs because of the reduced longevity of deionizer filters while potentially increasing the safety risks of the fluids in the vehicle. To reduce safety risks and maintenance costs, a critical consideration for all heat exchangers in the coolant circuit of the fuel cell stack is how clean the surface is from solder and flux residue and how conductivity changes over time and temperature in actual operation.

The EVantage™ Fuel Cell Stack Cooling Package by Modine® is designed to intelligently meet the thermal management needs of a fuel cell stack while ensuring conductivity requirements are also met. To understand how this is accomplished, let’s take a closer look at three key features of the FC-SCP – conductivity, predictive cooling, and waste heat recovery.

- Conductivity: The Fuel Cell Stack Cooling Package (FC-SCP) utilizes proprietary Modine® heat exchanger and manufacturing technologies that result in a flux-free heat exchanger required to meet Today’s most stringent fuel cell coolant loop conductivity requirements. Modine also specializes in the actual conductivity testing method to ensure conformance.

- Predictive Cooling: A typical fuel cell cooling package will allow a 10 to 15°C temperature swing at the fuel cell stack. Often, the temperature rises in the stack at a rapid rate. By the time the thermistor in the loop reads the temperature and commands the cooling package to lower the coolant outlet temperature, the fuel cell stack will have experienced a significant temperature swing. For best efficiency (and therefore longest vehicle range), the fuel cell stack will ideally be kept within 2-3°C of the optimal temperature set-point. Tight temperature control will also improve the durability and lifetime of the stack by minimizing degradation from temperature swings. With the EVantage™ FC-SCP’s proprietary predictive cooling mode, an intelligent algorithm is used to minimize temperature swings at the fuel cell stack, extending the range, efficiency, and lifetime of the stack.

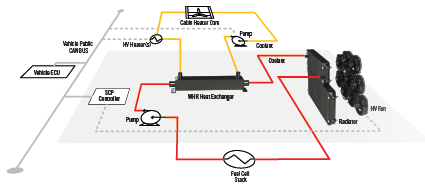

- Waste Heat Recovery: In electric vehicles, cabin heating can be a key contributor to increasing power draw on the vehicle’s battery pack during cold weather, reducing range. Modine has developed an all-aluminum coolant-to-coolant heat exchanger specifically designed for the fuel cell and cabin heating operating points. This heat exchanger scavenges waste heat from the fuel cell stack coolant and transfers it to a secondary coolant loop which can then be used by the vehicle’s HVAC system for the cabin for heating to save on power draw.

The schematic on the left shows a typical fuel cell stack cooling package (FC-SCP) design which has a radiator to reject heat from the coolant to ambient air and an array of fans to increase airflow through the radiator to maximize heat transfer. The speed of the fans will be modulated depending on the cooling needed to minimize power draw. In addition to the FC-SCP, coolant pumps and a surge tank may be added to the coolant loop to help manage the flow of the coolant to and from the vehicle’s fuel cell stack and the FC-SCP.

An FC-SCP is designed to be a complete, plug-and-play system with an integrated master controller to intelligently control the operation of the fan array and coolant pumps. A Stack Cooling Package provides a complete system, including all necessary heat exchangers, fan array, wiring harness, as well as a master controller with tailored firmware to provide complete operation upon delivery, enabling fast and easy integration into the vehicle’s chassis.